Olstas Company uses innovative technology of agricultural production:

Tillage system “Strip-Till”

Since 2013, the company uses 16-row units Orthmann (USA) for strip tillage. Since autumn, the units treat the land in strips (with simultaneous adding of liquid and dry fertilizers). In spring, cultivated crops (corn, sunflower) are sown in treated strips.

This technology reduces the number of passes and significantly increases the efficiency of fertilizers.

Besides, Strip-Till significantly reduces the time of land preparation under crops, thus reducing the need for equipment (depreciation, operators, etc.).

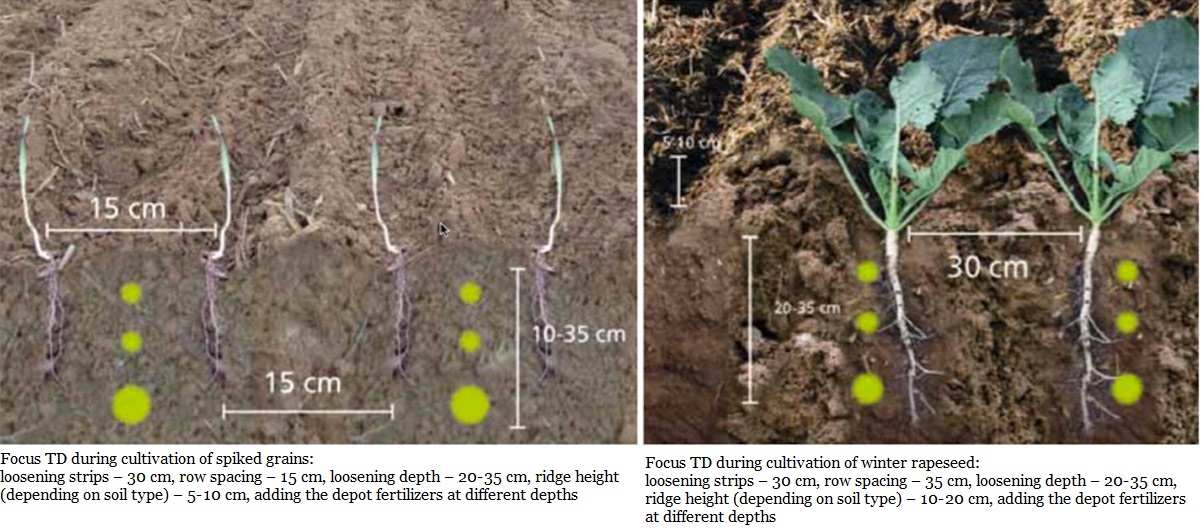

Since spring 2016, Strip-Till is also used for sowing the crops, soybean, and rapeseed. The work is performed by novelty in agricultural machinery – combined sower Horcsh-Focus, which deeply loosens the rows for planting, adds fertilizers at different depths, and seeds the crops (all in one pass).

Strip-Till cultivation with adding of liquid fertilizers

Differentiated adding of complex fertilizers

Automatic control systems

Automatic control systems (RTK accuracy) are based on main equipment, including the combine harvesters.

Use of the above technology ensures “pass-to-pass” accuracy of different equipment (deviation up to 2.5 cm), which is imperative for Strip-Till technology (row cultivation).

Autopilot installed on tractor (harvester, self-propelled sprayer) lets the operator fully concentrate on work (fertilization, sowing, dosing of chemicals, harvesting), as there is no need for “steering”.

Another advantage of autopilot is automatic transfer of field map (with pass data) from one unit to another. That is, first pass of equipment forms the field map used by all subsequent machines. As a result: no errors of tillage, use of plant protection means, differentiated adding of fertilizers, sowing with switched-off seeding units (when approaching the sown areas), etc.

Rubin gigant Lemken

Turbochisel Great Plains

Plow Lemken Euro

Soil liming

Horsch Focus

John Deere 1770 – corn sowing with adding of liquid fertilizers

GPS control

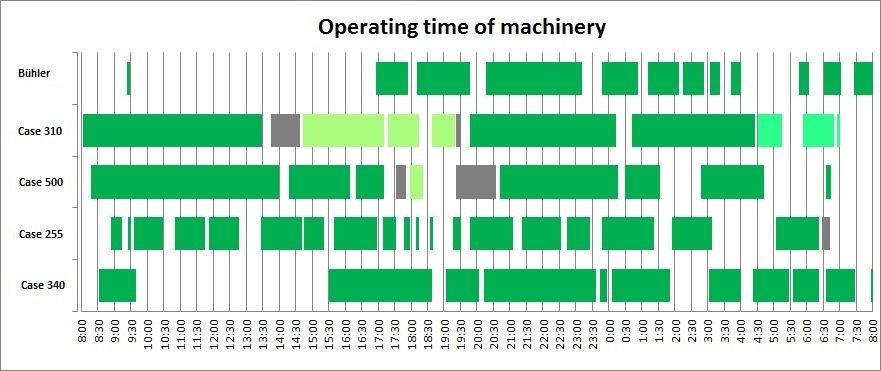

GPS control of equipment operation and traffic (Agrocontrol)

Each unit of equipment is provided with electronic GPS sensors, which ensure the online data on location of certain unit, its velocity, fuel consumption, treated area, etc.

This system enables full control of equipment in the field (progress of work), movement of vehicles during grain transportation from the field, and other transport operations.

Use of Agrocontrol ensured the company transfer to electronic accounting of agricultural resources, work hours, and performed work.

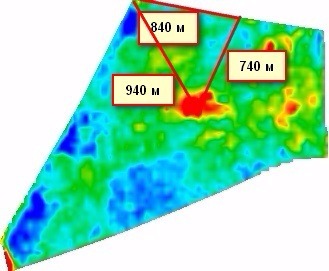

Cropio system (satellite monitoring of crops)

With Cropio program, experts of Olstas analytical department ensure the weekly monitoring of crops, while obtaining the crop vegetation index in online mode, identifying the problem areas in the field (for further visual/laboratory studies), determining the field readiness for harvesting, need for desiccation, etc.

For detailed inspection of crops, the company applies quadcopter with ability of 4K video/photo shooting. Use of quadcopter lets the company management have detailed information on status of crops, problem areas, and other data required for operative management decision-making.

Precision farming systems

Olstas opens a season of 2017 with introduction of new precision farming systems – differential adding of fertilizers by pneumatic unit Rauch, sower Horcsh, applicator for inter-row adding of liquid fertilizers Farmet, and Strip-Till cultivator Orthmann.

Productivity map

Adding of fertilizers with Rauch

John Deere 4730

Preparation of solution for sprayer

Harvesting with autopilots